Pakistan has a long history of carpet making. The earliest carpets made in Pakistan are known as “Ghiya” and date back to the 15th century. These were usually made from wool but also included cotton and silk.

History of Carpet Making in Pakistan

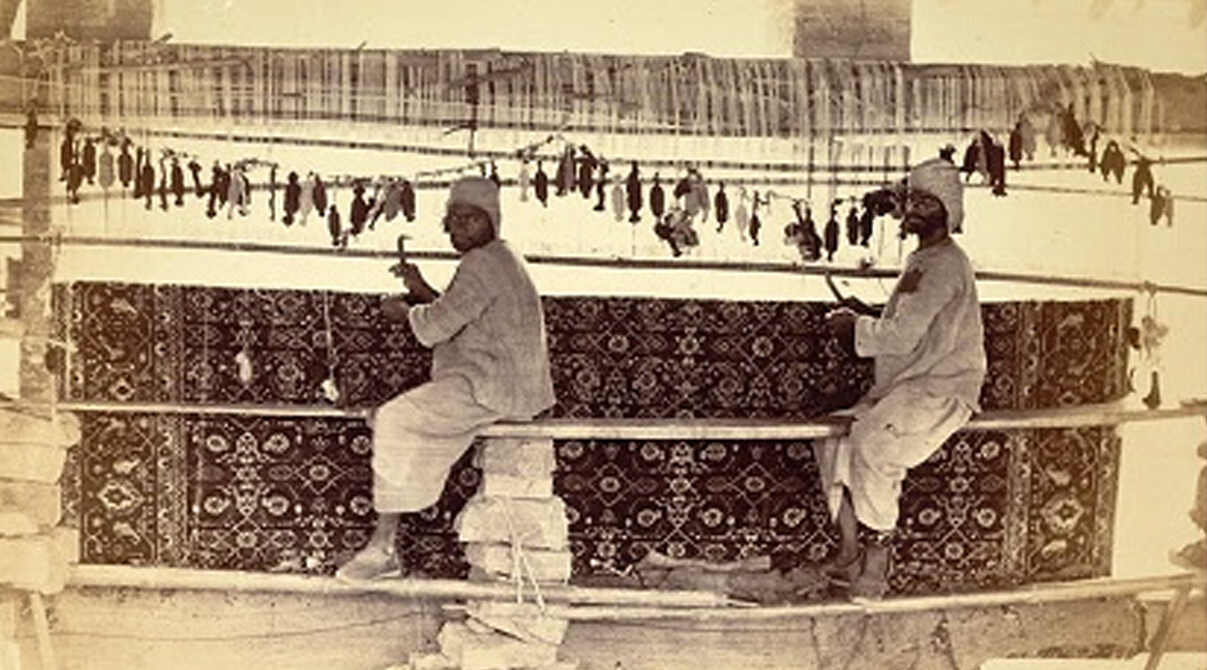

16th Century – Use of Wooden Loom

In the 16th century, carpets from Lahore, Kashmir, and Multan became popular. During this time, these carpets were used to cover walls and floors. Carpet weavers wove handmade carpets by using a wooden loom and it took about 30 hours to complete.

18th Century – Use of Machinery

In the 18th century, weavers began using machinery in order to produce handmade carpets quicker. However, hand-weaving techniques remained the standard until the 19th century when hand-weaving was no longer popular.

19th & 20th Century – The Taylor Machine

Earlier, in the mid-19th century, the British had colonized India and Pakistan. Britain was looking for ways to get into the textile trade. In 1868, a man named John Taylor came up with a machine that could weave carpets. The Taylor Machine was patented in 1884 and produced carpets at an incredible speed. By 1895, the machine became widely popular throughout England and Europe.

The introduction of the Taylor Machine was a major step in the development of hand carpet making in Pakistan. By the 1930s, carpet weaving in Pakistan had become very popular. The popularity of the Taylor Machine helped to expand the industry throughout Pakistan.

In the 1940s and 1950s, the British government in Pakistan introduced various laws to help the industry. For example, there was a quota system that required the government to buy the entire production of the carpet industry.

The introduction of the Taylor Machine was a major step in the development of carpet making in Pakistan.

The development of the industry expanded the industry. In the 1960s and 1970s, the carpet industry was one of the largest employers in Pakistan. At this time, the majority of carpets were exported to the Middle East, Iran, and Africa.

After the introduction of the Taylor Machine, carpet making quickly became a major industry. However, it faced competition from other industries. In the 1980s, the carpet industry in Pakistan went through a period of decline. This led to layoffs in the industry and an overall decrease in the demand for carpets.

By the 1990s, carpet making in Pakistan had completely changed. The demand for handmade carpets had declined. A lot of small carpet manufacturers began producing low-quality carpets. Selling these carpets at low prices, hurt the carpet industry.

The Current Era

The growth of the carpet industry in Pakistan is still strong. There are still many companies that specialize in the production of high-quality carpets. These companies mainly export carpets to the Middle East, the United States, and the European Union.

Punjab dominates the carpet industry while Lahore is the primary manufacturer of carpets in Pakistan. Women run the majority of the carpet industry. In order to begin working in the industry, a woman will need to own a sewing machine and access to a weaver.

Men do most of the handmade carpet weaving, while women do the majority of the actual sewing.

Read More: Baluchi Rugs: Epitomizing their Culture Beautifully

The Carpet Industry of Pakistan

Handmade carpets of Pakistan have their roots in traditional craftsmanship. Weavers pass the technique of creating handmade carpets from generation to generation.

In recent years, the craft of hand-weaving has gained popularity among a new generation of craftsmen. Hand made carpets of Pakistan are known for their softness and delicate appearance.

In recent years, handmade carpets have emerged as one of the most popular types of carpets in the world. Today, the weaving process of many carpets utilizes natural fibers; including wool, cotton, silk, linen, polyester, and acrylic fibers.

However, this type of rug is quite expensive and hard to maintain due to its high cost. The production process of these rugs is complex and requires highly skilled workers. Moreover, the cost of raw materials such as wool and silk is also very high.

Machine vs Handmade Carpets

A carpet machine, on contrary to hand-weaving, is easy to maintain and requires minimum maintenance. The use of a machine also saves time. It can be installed and removed quickly.

The production of a machine-made carpet is not much different from the production of other carpets. However, the major difference is that a machine makes a carpet faster, easier, and cheaper.

The Loom Method

Typically, the production of handmade carpets uses the ‘looms’ method. The ‘loom’ method is a traditional way of weaving that uses a continuous web of yarns and a weaver. This is a complex method and requires highly skilled weavers who have ample training in the art of weaving.

The loom is basically a rectangular frame that has a large number of horizontal and vertical wooden beams. The production of a variety of woven products use a shuttle and weft.

The Laid Method

On the other hand, making the most popular type of carpet, the “laid” handmade carpet demands the use of carpet machines. A machine that produces a patterned or a random-patterned design makes these rugs.

A carpet machine creates a continuous loop of yarns, which is then fed through a series of rollers that produce a pattern or design in the fabric. The design can be either a random pattern or a geometric or a floral pattern.

Weavers use the “laid” method to make a variety of rugs, including the “laid” carpet, the “cut pile” carpet, the “loop pile” carpet, and the “tufted” carpet.

The Flat-weave Method

In addition, a machine is also used to produce a flat-weave carpet.

A flat-weave handmade carpet requires the parallel arrangement of the warp and weft yarns to each other. The direction of the weft thread is perpendicular to the direction of the warp thread.

Unlike the “laid” carpet, the flat-weave carpet is easier to cut and lay on the floor. However, flat-weave carpets are typically expensive and are also harder to maintain than “laid” carpets.

In recent years, the production of “cut pile” carpets has increased. Manufacturing of these rugs involves a combination of “cut-pile” yarns and base yarn.

Production of these rugs requires carpet machines. However, it is difficult to control the direction of the “cut-pile” yarns with the same degree of precision as in the production of a “laid” carpet.

Additionally, the use of the “laid” method produces a stronger, more durable, and more attractive carpet than that created by a machine.

Wool and Silk Carpets

There are two main categories of carpets: wool and silk. Traditionally, owners of public places, such as shopping malls or restaurant owners use woolen carpets to cover floors and make them appealing. Silk carpets, on the other hand, private settings and homes usually have silk carpets on their floors to give warm and aesthetic vibes.

These rugs are usually soft, durable, and resilient. They have a pleasant scent. They are easily washable using soap and water.

However, wool and silk carpets are expensive. They are also more difficult to clean than machine-made carpets. In addition, these rugs are also more prone to fading.

Handmade Carpets as Exports

The handmade carpet industry has grown tremendously in Pakistan over the past few decades. The production of carpets in the country is worth billions of rupees.

The carpet industry in Pakistan is very large. However, the changing lifestyles of Pakistani society pses a major threat to the growth of this industry.

In Pakistan, there are approximately 2,400 carpet manufacturers. The majority of these manufacturers are located in the Punjab province.

There are also a large number of carpet exporting companies in the country.

Pakistan exports most of the hand-loomed carpets to foreign countries. The international markets of Europe, the Middle East, and Asia are the major selling points for these carpets. The main purpose of exporting handmade carpets is to raise the incomes of weavers. The carpet industry in Pakistan has grown a lot over the past few decades.

The production of carpets increased from 5,000 meters in 1980 to 2,000,000 meters in 2006.

Currently, the production of carpets in Pakistan is around 3.3 million meters per year. This figure is expected to rise to 9 million meters.

Pakistan manufactures a wide range of carpets, including jacquard, tapestry, and shag carpets.

Types of Carpets

There are many types of carpets in the Pakistani market. Some examples include:

Handmade Carpet

This type of handmade carpet has been woven or knitted by hand. It is an art form that originated in Pakistan.

Machinery Carpet

Manufacturing this type of carpet uses a machine which applies heat to smear a layer of polypropylene onto the woven backing.

Wool Carpet

“Gauze knitting” is a method widely in use for making handmade woolen carpets. It’s a very traditional method used in Pakistan and India.

Cotton Carpet

This type of carpet is also called “cotton weave.” In Pakistan, carpet making widely uses cotton fiber as a raw material as compared to other fibers.

Carpet Weaving as a Job

In recent years, the increased use of modern tools and methods has made the carpet weaving industry in Pakistan a low-paying and unstable career.

Many weavers have lost their jobs. In addition, the decreasing demand for handmade carpets has affected the livelihoods of many weavers.